Electricity networks are under pressure. Not only do they need to modernise rapidly to meet the demands of the digital age and a decentralised, renewables-driven grid, but they must also play a central role in tackling climate change.

That’s according to Wagners Composite Fibre Technologies (CFT) Global Utilities Lead, James Lorrimer who said in the race to decarbonise, much of the attention is focused on generation and storage. Yet, the humble utility pole, millions of which support electricity networks around the world, offers a surprisingly powerful opportunity for emissions reduction and long-term sustainability.

“Transitioning from traditional timber poles to Fibre Reinforced Polymer (FRP) composite alternatives represents a significant step forward in decarbonising electricity distribution infrastructure,” James Lorrimer said.

“Timber poles have been the backbone of electrical networks for over a century. They’re familiar, relatively low-cost, and backed by decades of standards and processes. But their environmental footprint is larger than many assume,” Mr Lorrimer said.

“Firstly, the production of timber utility poles involves harvesting mature trees,typically hardwoods such as eucalyptus, and softwoods like Douglas fir, or pine. These trees take decades to grow and, when harvested, release the carbon stored during their lifespan,” he said.

“While forests can be replanted, the net carbon benefit depends on complex variables including soil disturbance, transport emissions, and whether or not the harvested wood is used in long-life applications.”

Secondly, timber poles require treatment to resist rot, termites, and environmental degradation.

“Creosote is still widely used as a timber treatment, but it’s a toxic, petroleum-based chemical that is now being phased out or banned in Europe and other regions. Not only does it leach out over time, creating long-term environmental risks, but it also carries a heavy carbon footprint given it’s derived from fossil fuels,” James Lorrimer said.

“Timber poles don’t last long, usually 30-40 years at best and even less in tough climates. That means they need to be replaced regularly, which adds more emissions through the full cycle of transport, installation and eventually disposing of chemically treated waste,” Mr Lorrimer said.

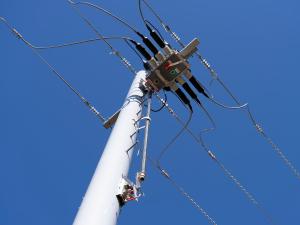

“Fibre Reinforced Polymer (FRP) poles are engineered to outperform timber in almost every category. What sets them apart from a sustainability perspective is their durability, resistance to environmental degradation, and the emissions they don’t produce,” he said.

“FRP poles don’t rot, rust, or require toxic chemical treatments. They’re inert, meaning they don’t leach harmful substances into soil or waterways, and they resist pests without needing hazardous preservatives.”

“In bushfire-prone areas, they can be fitted with a protective fire sleeve to handle extreme heat; while in coastal or humid environments, they deliver superior resistance to corrosion.”

The carbon benefits of FRP utility poles are compounding over time through:

- Longer lifespan: FRP poles can last 80–100 years, double or more than timber, drastically reducing replacement frequency, transport, and disposal emissions.

- Lighter weight: FRP poles are significantly lighter than timber, meaning more can be transported per trip, and they can often be installed with smaller, more fuel-efficient machinery.

- Low maintenance: With fewer inspections, no need for re-treatment and minimal to zero intervention, there is far less reliance on service trucks, each trip otherwise adding to emissions.

Biological hazards are a risk for timber utility poles, especially as treatments designed to arrents attacks become less effective through chemical restrictions or banning, for example Creosote.

When considering the environmental impact of a product, Life Cycle Assessments (LCA) offer a cradle-to-grave view from raw material extraction and manufacturing to transport, use and disposal.

“When LCAs are used to review the environmental performance of FRP utility poles, the results are compelling,” James Lorrimer said.

“While the upfront embodied energy of FRP poles can be higher than timber or steel, owing to the use of resins and glass fibre production, the picture changes dramatically when you look at the whole-of-life emissions. The avoided impacts from repeat manufacturing, transport, and waste disposal over multiple replacement cycles give FRP a decisive advantage,” Mr Lorrimer said.

“In fact, the results of a case study showed that when the utility poles made from Wagners FRP and galvanised steel were compared across the full life cycle and over a 100-year reference service life, FRP showed 39% less total global warming potential impacts than the galvanised steel,” he said.*

*These are the results of an LCA comparing Wagners CHS 301 (utility pole) to a galvanised steel utility pole, which has been third party reviewed and verified. Results could vary depending on the specific design of the poles being compared. Please note, no LCA for timber utility poles was available globally to compare at time of printing.

“But, there’s also another dimension to decarbonising poles, and that’s resilience. Climate change is increasing the frequency and intensity of natural disasters like wildfires, cyclones, and floods. Timber poles are particularly vulnerable in these scenarios, often requiring rapid replacement after catastrophic failure that lead to network outages.”

“Every emergency replacement event comes with high emissions: aerial transport, fast-tracked logistics, heavy equipment mobilisation, and significant waste.”

“But by contrast, FRP poles are disaster-resilient by design, often remaining standing and functional after events that destroy timber assets. Avoiding one such replacement can offset much of the embodied carbon in the FRP pole’s manufacture.”

Governments around the world are recognising the environmental and health risks associated with timber preservatives like creosote.

“The EU has progressively tightened restrictions, and countries like Norway and Sweden are already phasing out creosote-treated utility poles. Australia has moved in the same direction, under growing scrutiny from environmental authorities and communities,” James Lorrimer said.

“This policy trend makes the transition to alternative materials not just an environmental imperative, but a compliance one as FRP poles offer a future-proof solution that aligns with ESG commitments, net-zero targets, and circular economy principles,” Mr Lorrimer said.

“In addition, the clean energy transition is placing new demands on distribution networks, more renewable connections, smart grid capabilities, and greater load variability. FRP poles are “smart grid ready”, with integrated ducting for fibre, sensors, and communications infrastructure that can be embedded during manufacture,” he said.

One of the lingering myths about FRP poles is that they’re too expensive.

“While upfront costs can be higher than untreated timber, this view ignores the dramatic total cost of ownership advantages”, Mr Lorrimer said.

“When asset owners factor in extended life, no need for chemical re-treatments, fewer replacements, lower to zero maintenance, reduced disposal and environmental compliance costs, the long-term financial case is clear,” he said.

“What’s more, innovations in manufacturing, scaling up of production, and growing demand are all contributing to reduced costs and improved availability of FRP utility poles.”

“And that transition is already happening in electrical networks in New Zealand, Canada, the United States, Australia, and parts of Europe; they’re all adopting FRP poles not just in trials, but as standard practice or in high-risk or high-cost environments.”

The power pole may seem like a small piece of the energy puzzle, but when multiplied across tens of millions of units globally, the impact is profound.

“Replacing aging, treated timber poles with lightweight, long-lasting composite alternatives is one of the simplest, most cost-effective ways to cut emissions from distribution networks and build climate resilience in the process,” James Lorrimer said.

“As we move towards a net-zero future, every decision about infrastructure must consider not only cost and performance, but also carbon. The shift from timber to FRP poles isn’t just an upgrade, it’s a declaration that sustainability is now at the heart of utility design,” Mr Lorrimer said.

“It’s time to see the power pole not as a static part of the past, but as a dynamic tool for a decarbonised future,” he said.

Interested in how composite poles can help your network decarbonise and modernise? Reach out to James to find out more about performance data, case studies, and deployment strategies using the Contact Us form on the website or by phoning or emailing James directly at https://www.wagnerscft.com.au/contact-us/