With 25 years of experience delivering pedestrian bridge solutions across Australia and around the globe, Wagners Composite Fibre Technologies (CFT) has unveiled a new product range aimed at making procurement faster, simpler and more cost-effective for customers.

The Signature Series is a collection of pre-engineered, off-the-shelf bridge designs, created to meet the most common infrastructure requirements seen across hundreds of successful projects.

Built on decades of experience and deep knowledge of Australian standards, the Signature Series streamlines everything from quoting to delivery while offering the same level of structural integrity and compliance that Wagners CFT is known for.

Spearheading the Signature Series is Project Delivery Lead, Mitch Kelly and Lead Estimator, Scott Brown.

“We have been delivering hundreds of pedestrian bridges over our 25-year history. During this time, our clients’ needs have been similar,” Scott Brown said.

“This includes requirements for vehicles or adherence to various Australian standards. These include, but are not limited to AS1170, AS5100, AS2156 and AS1428,” Mr Brown said.

“What we have decided to do is create a list of off-the-shelf standardised designs which are ready to be constructed and certified, removing the need for custom designs for each individual project,” he said.

“In a nutshell, the Signature Series is Wagners CFT’s range of pre-engineered pedestrian bridges built from the company’s best designs over the past 25 years.”

“It allows you to select and order a bridge quickly and in accordance with Australian standards.”

Pictured – 18m x 3.8m FRP truss bridge.

Pictured – 18m x 3.8m FRP truss bridge.

Customers choosing a Signature Series bridge can expect a range of benefits from day one.

“The first major benefit customers who purchase a Signature Series bridge will experience is cost savings,” Scott Brown said.

“Signature Series bridges inherently require less design work and bracketry and connection details have also been standardised allowing us to provide cheaper connections due to bulk buying power,” Mr Brown said.

“Another benefit is reduced lead times. For those that have been involved in the process, designing custom bridges can be a very drawn-out process with a lot of back and forth between multiple stakeholders,” he said.

“Standardised designs reduce the need for this as clients can choose the exact design they require for the project from the get-go and receive drawings with their quotation.”

“You will also benefit from predictability and familiarity. The whole point of the Signature Series is that the bridge ordered in a few years’ time will have the same look and feel as a bridge ordered today.”

“This uniformity across our structures also intends to make life easier for our installation contractors through bridge leads, familiarity with the product and lifting points on our structures.”

Pictured – 10m FRP girder bridge.

Pictured – 10m FRP girder bridge.

The Signature Series debuts with pre-engineered girder and truss bridge designs ready for fast deployment.

“The first and headline structure type for the Signature Series is our clear span pedestrian bridges,” Mitch Kelly said.

“We have recently completed the design of a range of girder and bolted truss style bridge solutions pre-engineered to Australian standards from three metres long right up to 30 metres long in four standard widths,” Mr Kelly said.

“These designs are available upon request and can be used for tender design purposes or instant procurement,” he said.

“When we say a girder bridge, it means multiple large beams side by side and joined together under the deck. The deeper the beams, the more rigid and the longer we can span.”

“This becomes inefficient with larger spans, so we offer a truss bridge solution for spans 16 metres onwards.”

“The Signature Series covers from very small spans right up to significant structures.”

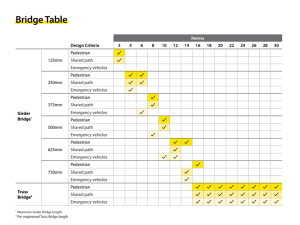

Pictured – The Signature Series bridge table.

Pictured – The Signature Series bridge table.

Signature Series bridges are designed to meet three loading criteria and come in four standard widths.

“We have designed these bridges to suit three loading criteria. These loadings are grouped based on commonly used Australian standards for structures,” Mitch Kelly said.

“The first criteria we have labelled as pedestrian has a three kPa live load and 1.4-ton point load. This is straight from AS1170 and AS2156 as a walking track class three loading for pedestrian structures,” Mr Kelly said.

“The second criteria is a shared path criteria which is the most common we see for our pedestrian infrastructure in Australia,” he said.

“It covers all bases, five kPa live load and 4.5-ton point load. This is a track class one from AS2156 and suits all shared paths. It is the best fit for the end application of the majority of our bridge structures.”

“The third criteria is the emergency criteria which is basically the same as a shared path except with a higher concentrated load to allow for vehicles up to a four-and-a-half-ton ambulance.”

“We have four widths as part of the Signature Series bridges. These are two meters, two and a half metres, three metres and three and a half metres.”

“These are clearable widths and have been chosen from a mixture of design codes. The most common widths that our bridges have been designed to over the past 25 years as well as being simple half meter intervals.”

Pictured – FRP truss bridge during assembly at Wagners CFT manufacturing facility.

Pictured – FRP truss bridge during assembly at Wagners CFT manufacturing facility.

The Signature Series bridges come with a range of compliant handrail and decking options, tailored to suit the most common pedestrian and shared path requirements.

“We have an extensive range of handrail options, all of which can be fitted to our bridges,” Mitch Kelly said.

“For simplicity, the most common two types being pedestrian and shared path are shown in our Signature Series and have covered 90% of the bridge structures we have supplied,” Mr Kelly said.

“The design loadings on these handrails are pulled straight from AS1170 and AS2556,” he said.

“The shared path barrier is also compliant with AusRoads6A which is a guide that is commonly being used around Australia at the moment for cycle weight compliance.”

“We have designed the bridges to suit our two most common FRP decking products to create a full Wagners FRP solution. These decking products are mini-mesh and covertop.”

“Covertop is more expensive but is required if you need the emergency vehicle loading or a closed surface finish.”

“The mini-mesh is the most common decking type supplied with our bridges and is a very well-known, tried and tested product and is perfect for shared path and pedestrian use.”

Pictured – Decking and handrail options in the Signature Series brochure.

Common questions about the Signature Series bridges include foundation design and flood loading, both of which have been approached with flexibility and efficiency in mind.

“One common question that has already come up with these pre-engineered bridges is whether foundations are included in the design. The short answer is no,” Mitch Kelly said.

“Due to the variability of sites and ground conditions across Australia and the world, as well as varying preferred install methods of contractors, we felt this was a good approach to the foundations for our bridges,” Mr Kelly said.

“It guarantees that the best and most efficient foundation option whether it be screw piles, micro piles or bored peers can be used in conjunction with our bridge designs to save on entire project costs for the asset owner,” he said.

“Another common query about our bridges is what flood load they are designed to withstand.”

“We have not selected a blanket flood loading for all our bridges as this could mean we are not supplying the most efficient bridge option for each span.”

“Instead, the flood load designed to withstand is different for each bridge and it is actually the maximum flood load the structure can withstand at deck level without needing significant changes to our design to accommodate. So it is our best, most efficient option.”

Pictured – A fully assembled FRP truss bridge being craned onto foundations.

Pictured – A fully assembled FRP truss bridge being craned onto foundations.

There are three levels of prefabrication available for Signature Series bridges.

“The first level of prefabrication is fully assembled and craned into position. This is by far our most common and easy for the guys to install on site,” Scott Brown said.

“We have got a team of bridge builders at Wagners CFT that specialise in building these structures. We build them to order and then deliver them to site in that scenario,” Mr Brown said.

“The second option is partial assembly. We have had to do this at times where there have been site constraints and we have not been able to get a truck right in where we want it to go,” he said.

“In this scenario, we prefabricate the truss sections and pre-drill the bearers as well.”

“Then we have the third option for prefabrication which is kit form. So this will be a piece-by-piece assembly on site.”

“This will be the most work for the contractor or installation contractor. Sometimes the site can be really remote and you need to helicopter gear in. In that scenario, kit form would be the way to go.”

Pictured – Partially assembled bridge being loaded for delivery.

Pictured – Partially assembled bridge being loaded for delivery.

Ordering a Signature Series bridge is simple and can be done online.

“We have tried to make the process as simple as possible and have narrowed it down to five steps. So we call it our five easy steps,” Scott Brown said.

“These steps are all laid out clearly in an online order form on our website to guide you through the process easily,” Mr Brown said.

“Step one is to choose the loading of the bridge. We have the pedestrian, the shared path and the emergency vehicle,” he said.

“Step two is to identify the bridge length in meters as per the table. We can do girder bridges up to around 14 to 16 metres and then after that it is going to be a truss bridge.”

“Step three is to work out the width of your bridge. We have four standard widths that we commonly see that we have nominated.”

“Step four is to select the decking that you would like as well as the handrail, whether that be the pedestrian barrier or shared path barrier.”

“Step five is to select your colours. We have the structural coating colours which would be for the bridge. Then we have the colours for the decking, the kick rail/handrail colours for our rails, and the balustrade colour as well.

“Then there is one more question which is for other details. So this can be the level of prefabrication, whether it is a budget for next financial year or anything else that you think would be relevant or good for us to know when we do up the price.”

Pictured – The five easy steps for online ordering.

Pictured – The five easy steps for online ordering.

With the Signature Series now established, Wagners CFT is looking ahead to future improvements and expansion opportunities.

“We want to continue to develop and improve the bridges to make sure that they are always the best that we can offer,” Mitch Kelly said.

“Feedback from clients, contractors and end users will play a key role in guiding ongoing improvements to ensure the Signature Series remains practical, efficient and fit for purpose,” Mr Kelly said.

“After that, the next step for us is moving into other structure types with a critical one being boardwalks which is a very common structure type for our FRP product,” he said.

“The plan is to launch the boardwalk series first up in the new year. They will be very similar styles to the bridges however, we will be focusing on a bay style approach to the boardwalk design.”

“So having designs completed for boardwalk bays under loading criteria and spans similar to the bridges.”

“Ideally for procurement, you follow a similar bay style approach and then from there we can take into different opportunities especially in the prefabrication space which we do for our bridges.”

“As the Signature Series continues to evolve, our focus remains on delivering smarter, faster and more consistent FRP solutions that meet the real-world needs of clients and communities.”

To watch the full webinar with Mitch and Scott visit – https://www.youtube.com/watch?v=3djPZcq_Rrw

Download the Signature Series brochure – https://www.wagnerscft.com.au/app/uploads/2025/07/J8540_WAG_Signature-Series-Brochure_Web.pdf

Order a Signature Series bridge now – https://efm18.share.hsforms.com/2GbV8ya2SQvaiK53MqOR5PA