Unprecedented rainfall throughout Townsville in February and March saw the region experience a 1 in 500-year flood; with some rainfall totals exceeding a 1 in 2000-year event in parts of the Ross River Dam catchment.

But Townsville’s new East End Boardwalk, despite being subjected to high levels of flooding, performed well beyond expectation, highlighting the durability and resilience of Fibre Reinforced Polymer (FRP).

Wagners Composite Fibre Technologies (CFT) Project Manager, Daniel Allen explains the design and construction of East End Boardwalk and why this FRP structure performed so well.

“In early February, Townsville received almost 300 millimeters of rain in 24 hours and all the way up to 710 millimeters in 72 hours which is, in some locations up there, rarer than 1 in 2,000-year event,” Daniel Allen said.

“Quite often North Queensland gets hit with these kinds of heavy periods of rain during the wet season but the sustained intensity of this event has been both remarkable and devastating,” Mr Allen said.

“We saw that the levels of the Ross Creek were between Q100 and Q200 events with levels rising above three metres. One of the great things and fortunate things in what we designed for is that the deck is designed to take those impacts,” he said.

“As per our design, our trusses and decks can be inundated with water. The trusses have been inundated twice in the first two years of its life cycle, so pretty impactful, especially when you consider a 1% design level occurrence.

Pictured – East End Boardwalk was designed to hug the banks of Ross Creek connecting key entertainment precincts in Townsville.

Pictured – East End Boardwalk was designed to hug the banks of Ross Creek connecting key entertainment precincts in Townsville.

The boardwalk is an incredibly important piece of council infrastructure for Townsville, linking various locations throughout the entertainment precinct, making travel between venues simple for locals and tourists.

“The project scope was to design and construct a new 280 linear meter long and 5 meter wide marine boardwalk. It’s part of a larger waterfront promenade network project planned by Townsville City Council,” Daniel Allen said.

“In stage two, there’s a requirement for design considerations for future works which was one of our major items which included Ross Creek Bridge. There’s a connection across the Ross Creek to Palmer Street, there’s also a connection into the local precinct and the boardwalk continuation to the Magnetic Island ferry,” Mr Allen said.

“It also included non-destructive structural integrity testing analysis over 100 linear meters of existing timber jetty and concrete structures and a partial demolition rectification of the existing structure to try and increase the design life of the existing structure,” he said.

“The project is located along Ross Creek. It runs along the Flinders Street car park in front of the Mad Cow on the main drag and passes just by the former post office and Trading Building previously known as Bullwinkle’s Nightclub, finishing in front of the Queensland Tropics Museum and just short of the old Great Barrier Reef Aquarium.”

“One of the main benefits is trying to connect the cruise terminal up there in the north all the way through to the stadium and connecting all the major eateries and entertainment areas along the Ross Creek.”

Pictured – East End Boardwalk had to be designed around flood impacts and pre-existing storm water surfaces.

Pictured – East End Boardwalk had to be designed around flood impacts and pre-existing storm water surfaces.

It was vital for Wagners CFT to design the structure around flood impacts and the levels of Ross Creek whilst also taking into consideration the pre-existing storm water surfaces surrounding the project site.

“One of our most major design risks was flood impact. It required a high level structure rising out of the creek bed up to 6 metres as a result of the Q100 RLS,” Daniel Allen said.

“It really shaped our design considerations for deck level connections and foundation types. Higher level floods can cause significant destruction in Townsville where the Ross River runs directly into Ross Creek,” Mr Allen said.

“Another challenge during construction was a rock wall failure. One of the buildings, the runoff led directly behind the rock wall and reloaded resulted in it slipping. That happened while we’re on Christmas holidays so it was a fun one to come back to,” he said.

Pictured – Boardwalk construction well underway with cranes lifting modular boardwalk pieces into place.

Pictured – Boardwalk construction well underway with cranes lifting modular boardwalk pieces into place.

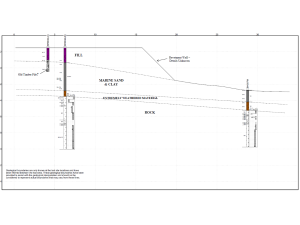

Geotechnical considerations also had to be made due to the harsh rock foundations.

“Our second major challenge was the geotechnical conditions which we were able to explore through the ECI which we were very fortunate to be able to explore up front,” Daniel Allen said.

“The tender provided the initial testing and bull hole data completed by the client. Wagners further investigated the area with some additional bore holes in the car park and down towards the buildings,” Mr Allen said.

“The depth of rock in the area was 4 to 5 metres and with socketing into the rock required, it subsequently affected some of the heritage listed buildings I talked about earlier and the private property owners and businesses close to the boardwalk,” he said.

“We actually had vibration monitoring equipment on the foundations of those buildings for the duration of the project. Another mitigating factor was the environmental impacts from drilling into rock. That had to be considered and largely led to a lot of our foundation decisions.”

“The top layer was a sandy fill gravel which could not reliably be used. Many of the piles would need a socket deep into the rock layer of depths up to 5 metres.”

Pictured – Geotechnical conditions presented challenges for the project.

Pictured – Geotechnical conditions presented challenges for the project.

The piling method was fine-tuned to ensure maximum efficiency and reduce any potential negative impacts to the environment.

“Originally we had a smaller foundation on the land and then a larger foundation on the marine socketing into the rock and effectively cantilevering. We decided, in the end, to reverse that and provide a large foundation in the car park due to access restrictions for large machines,” Daniel Allen said.

“We installed a generic 400 millimeter diameter steel reinforced bored pier socketing into a dense layer of up to 1.2 metres. The steel casing was used to sleeve to the rock layer so encompassing all that fill before the rock hammer was provided a clean socket for the cage,” Mr Allen said.

“We had vibration monitors allocated to the businesses and buildings around the area which were clear when completing this section but as we got closer to the buildings we started to see some higher results that led to the rock wall failure. This led to changing the design in the location behind the buildings and effectively it was due to having a very confined space, not as much room to move in there,” he said.

“We obviously were hitting higher readings on the noise vibration monitors so we were starting to see that f impact on the buildings could be possible, which we wanted to avoid so we changed to a 90-millimeter cased micropile with a concrete foundation that seals it all together, so a smaller machine was used to get those great result.”

“We reduced the footprint and environmental impact in that area by changing to those micropiles. It was also very cost-effective and allowed for program acceleration in that area so overall a very good change of ideas.”

Pictured – Through thinking outside the box, project managers were able to reduce overall costs by reducing the number of piles required by 50-percent.

Pictured – Through thinking outside the box, project managers were able to reduce overall costs by reducing the number of piles required by 50-percent.

Overall, the project was a great success leaving all parties involved happy with the end product and its performance.

“There was a $3 million reduction in price from initial tenders so a 30% reduction in cost which I know our client was very happy with,” Daniel Allen said.

“We were able to risk mitigate from the initial 70 large piles to just 16 marine piles and 19 land piles, really using the longer truss connection back to a really bulked up deck that went back into the larger land piles,” Mr Allen said.

“Further down the creek we were able to reuse some of the existing infrastructure. We had integrity testing return a real positive result on that and one of the major benefits is that the Wagners CFT sections were modular and can be removed for future planning considerations,” he said.

“We haven’t seen any issues with design implications with the structure on its completion so really a very fortunate and great result for the whole team.”

To hear the fully story of East End Boardwalk watch this on demand webinar featuring Wagners CFT Project Manager, Daniel Allen https://youtu.be/-pu8mL1jL_w