Eager to learn more about how Wagners Composite Fibre Technologies (CFT) produces its distinct Fibre Reinforced Polymer (FRP)? Explore how we transform glass and liquid resin into high-performance structural profiles using pultrusion enhanced by our unique pull‑winding technique.

Strength and Innovation of FRP

Fibre Reinforced Polymer (FRP), also known as reinforced plastic or composite plastics, is a class of advanced engineering materials composed of high‑strength glass fibres (or other reinforcing fibres) bound together in a polymer matrix. By combining a lightweight material with exceptional load‑bearing capacity, FRP delivers an outstanding strength‑to‑weight ratio compared with traditional materials like steel, timber or concrete.

At Wagners CFT, we harness a state‑of‑the‑art FRP manufacturing process to turn raw fibrous material into precisely shaped, high‑performance structural profiles. The most notable difference from other producers of FRP is our use of continuous pultrusion enhanced by our proprietary pull‑winding technique.

Below, you will learn more about each stage of how FRP is made, from the selection of raw materials to the final inspection of the finished product and beyond. We ensure every component delivers maximum strength, consistency, and long-term reliability. Our FRP is perfect for applications across various industries and infrastructure, including marine, industrial and utility sectors.

What is FRP?

FRP, or Fibre Reinforced Polymer, is a high-performance composite material made by combining strong reinforcing fibres with a durable polymer resin.

The result is a lightweight yet incredibly strong material that handles high loads and offers exceptional design flexibility.

Unlike traditional materials (e.g. steel or timber), FRP is inert: it is fully resistant to rot, rust and corrosion, making it ideal for harsh environments.

FRP Materials: The Building Blocks

FIBREGLASS REINFORCEMENTS

High-quality boron-free electrical and corrosion resistant (ECR) glass fibres are the primary reinforcement material. These continuous filaments deliver the tensile strength and stiffness essential for structural performance.

VINYL ESTER RESINS

The resin system plays a critical role in the structural integrity and durability of FRP composites. Wagners CFT uses catalysed vinyl ester resins due to their superior chemical resistance compared to epoxy. The resin is precisely mixed on-site with catalysts and accelerators to control cure kinetics.

SURFACE VEIL

A synthetic surface veil is incorporated into the laminate to produce a smooth finish, shield against UV degradation, and encase the glass fibres. This layer enhances both the aesthetics and long-term durability of the final FRP product.

The Pultrusion Process: Step-by-Step

Understanding Pultrusion:

Pultrusion is a continuous manufacturing process where raw materials, specifically glass fibres and resin, are pulled through a heated die to create uniform composite profiles. This method allows for the production of consistent, high-strength FRP sections.

Wagners’ Proprietary Pull-Winding Technique:

Wagners CFT has refined the traditional pultrusion process by incorporating a proprietary pull-winding technique. This advanced variation enhances the structural integrity of FRP products by optimising fibre alignment and resin distribution, resulting in profiles with superior mechanical properties.

Manufacturing Steps

Material Preparation: Glass fibre rovings are drawn from racks and guided to achieve the desired shape, orientation and layering. A surface veil is incorporated to improve surface finish and provide resistance to UV degradation.

Resin Impregnation: The aligned fibres are saturated with catalysed vinyl ester resin, ensuring thorough impregnation of all fibre filaments.

Heating and Curing: The resin-saturated fibres are pulled through a heated die, initiating a chemical reaction that cures the resin and solidifies the composite profile.

Cutting and Finishing: The continuous profile is cooled, cut to specified lengths using a moving cut-off saw and finished according to project requirements.

Why Wagners CFT Developed their Pull-Winding Process

Wagners CFT developed their proprietary pull-winding process as an alternative to the hand lay-up, automated pre-form process and vacuum bagging methods with an aim to address specific challenges and optimise the manufacturing of FRP products.

Wagners CFT began utilising the pull-winding technique in 2002, developing a proprietary process that integrates pultrusion and pull-winding to create high-performance FRP profiles. This innovation enabled the production of large, hollow rectangular composite profiles, which were previously challenging to manufacture efficiently.

By adopting and refining the pull-winding technique, Wagners CFT addressed specific challenges in structural applications, such as achieving high strength-to-weight ratios and resistance to environmental degradation. The advancements in this process have positioned Wagners CFT as leading FRP manufacturers for infrastructure projects.

How it works: Continuous Pultrusion & Pull‑Winding

Wagners CFT employs a continuous pultrusion process as the flagship method for its FRP manufacturing process. Continuous pultrusion is central to Wagners ability to produce their sought-after, high-strength, durable FRP products.

This process involves several key stages:

Creeling: Fibreglass roving spools are mounted on tension-controlled racks. The glass fibres are drawn from these spools and mats to form the reinforcement for the composite.

Resin Impregnation: The fibres pass through a resin bath or injection chamber where they are fully saturated with catalysed vinyl ester resin. This ensures a thorough wetting of each filament, which is crucial for the mechanical properties of the final product.

Pre-Forming Guides: The resin-saturated fibre bundle enters a series of shaping plates that guide it toward the desired cross-sectional geometry, i.e. the required profile. These guides ensure the fibres are properly aligned and oriented before entering the curing stage.

Heated Steel Die (Forming and Curing Die): The fibre bundle enters a heated steel die that defines the final cross-section of the composite profile. Temperatures within the die typically range from 100–160°C, initiating the curing process, transforming the liquid resin into a solid matrix.

Pulling System: A synchronised hydraulic puller grips the cured profile and pulls it continuously through the die. This ensures the continuous rovings remain taut and aligned, maintaining the load-bearing capacity of the FRP composite.

Cooling and Cut-Off: Exiting the die, the profile passes through cooling stations to solidify further. A saw then cuts the profile to the specified lengths without stopping the production line.

Wagners CFT’s Proprietary FRP Elements

Wagners CFT has pioneered their own pull-winding process that sets its FRP manufacturing apart from conventional methods. This innovative technique enhances the mechanical performance and structural integrity of FRP profiles, making them suitable for demanding infrastructure applications.

Precision Helical Reinforcement for Enhanced Structural Performance

A distinctive feature of Wagners CFT’s pull-winding process is the application of additional reinforcing fibres helically around the core. This method involves computer-controlled winding heads that lay fibres at precise spiral angles, enhancing hoop strength and torsional rigidity. Such reinforcement is crucial for applications requiring high resistance to twisting and external pressures, like utility poles and bridge components.

Targeted Resin Infusion for Optimal Structural Integrity

In addition to mechanical enhancements, Wagners’ process incorporates an engineered resin injection system, minimising voids and maximising structural strength. This precise resin application ensures that the final product maintains consistent quality and durability, even in challenging environments.

By integrating these proprietary techniques, Wagners CFT delivers FRP profiles that offer superior performance compared to traditional manufacturing methods. Their commitment to innovation positions them at the forefront of FRP technology.

Benefits of Pull-winded FRP

ENHANCED STRENGTH AND STABILITY

The pull-winding process allows for continuous fibre alignment, which is crucial for achieving high tensile strength and stiffness in the final product.

CONSISTENCY AND QUALITY CONTROL

By integrating the resin injection directly into the pull-winding process, Wagners ensures uniform resin distribution and fibre wet-out. This integration reduces the potential for defects such as air voids or resin-rich areas, which can occur in resin bath systems.

COST-EFFECTIVENESS FOR HIGH-VOLUME PRODUCTION

While automated pre-forming and pre-preg material layup offer high precision, they often involve higher material and equipment costs. Wagners’ pull-winding process balances cost and performance, making it suitable for large-scale production without compromising on quality.

ADAPTABILITY TO COMPLEX PROFILES

The pull-winding process is versatile and can produce a wide range of cross-sectional shapes, accommodating the diverse needs of infrastructure applications. This adaptability is advantageous over traditional methods, which may require retooling or extensive manual labour for different profiles.

Advantages of FRP Products Manufactured by Wagners CFT

High Strength-to-Weight Ratio: FRP profiles are approximately 80% lighter than steel yet maintain comparable strength, facilitating easier handling and installation.

Corrosion Resistance: FRP’s inherent resistance to corrosion makes it ideal for environments exposed to moisture, chemicals or saltwater, reducing maintenance needs or replacement timeframes.

Non-Conductive Properties: FRP is naturally non-conductive, enhancing its safety in electrical infrastructure applications.

Design Flexibility: The pultrusion process allows for customisable shapes and sizes, meeting specific project demands are met with precision.

Quality Assurance and Testing

Rigorous Testing Protocols

Each FRP product undergoes stringent quality checks to ensure compliance with industry standards. This includes mechanical testing to verify strength, stiffness and durability.

Certifications

Wagners CFT is ISO9001 and ISO45001 certified, affirming the business’s commitment to quality, customer satisfaction and continuous improvement together with proactively managing workplace safety, preventing work-related injuries and illnesses, controlling risks and complying with relevant laws and regulations.

100-year Design Life

Wagners FRP products are designed to meet a minimum service life of 100 years. To ensure long-term durability, all FRP components are coated with a UV-resistant layer that has undergone over 25,000 hours (equivalent to 125 years) of QUV-B testing in accordance with ASTM G154, demonstrating no degradation to framework integrity.

Sustainability and Environmental Impact

Eco-Friendly Manufacturing

The pultrusion process is energy-efficient and minimises waste, contributing to environmentally sustainable manufacturing practices.

Longevity

FRP products have extended service lives, reducing the need for frequent replacements and conserving resources over time.

FRP Manufacturers Australia & Worldwide

Wagners CFT carries out all FRP pultrusion production at the company’s manufacturing facility in Wellcamp near Toowoomba, Queensland. From this Toowoomba plant, Wagners ships FRP sections both nationwide and overseas. Producing all FRP products in a single location allows Wagners to tightly control materials, process parameters and quality, ensuring consistency in every profile.

Wagners CFT’s innovative manufacturing process, combining high-quality materials with advanced pultrusion techniques, results in superior FRP products that offer strength, durability and design versatility. For more information or to discuss potential projects, please get in touch.

EXPLORE WAGNERS FRP SOLUTIONS

MARINE INFRASTRUCTURES

Pontoons, Wharves, Jetties and Trident Marine Piles

ELECTRICAL INFRASTRUCTURES

Crossarms, Utility Poles and Light Poles

WATER TANK COLUMNS

Water or Sewerage Tank Columns

PEDESTRIAN INFRASTRUCTURES

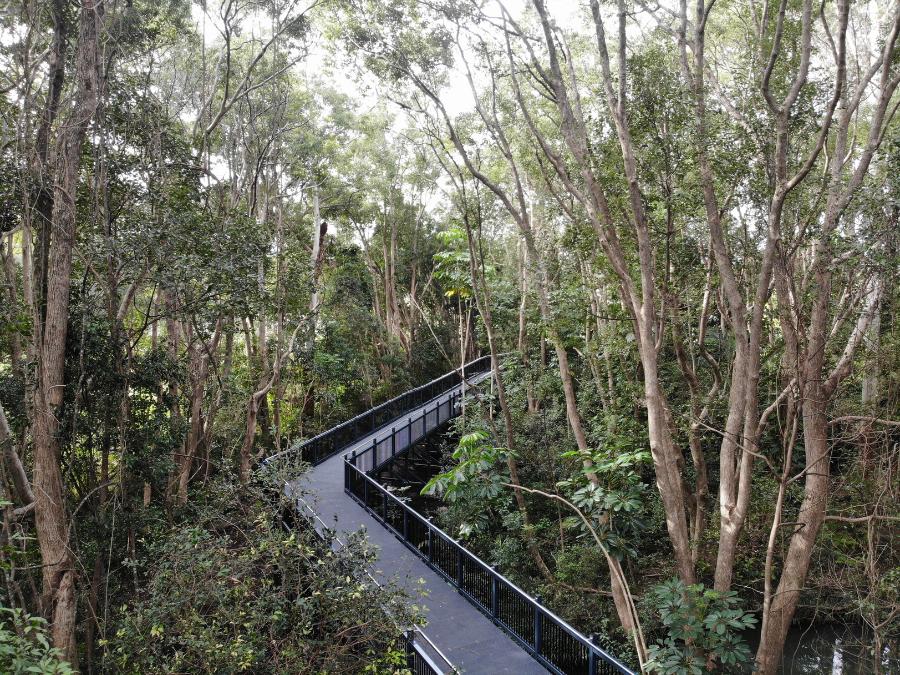

Boardwalks, Pedestrian Bridges and Decking

TRAFFIC INFRASTRUCTURES

Road Bridges and Timber Bridge Rehabilitation

STREET & PARK INFRASTRUCTURES

Shelters and Viewing Platforms

Have a project in mind?

Book a project deep dive with us and work through your projects plans and problems with the experts!