Fifteen years after the first commercial installation of Wagners Composite Fibre Technologies (CFT) Fibre Reinforced Polymer (FRP) piles in Mackay, Queensland, Wagners CFT piling products, methods and techniques have established a proven track record in structural performance, geotechnical reliability, and long-term durability.

With thousands of piles now installed across Australia, the United States of America, and the United Kingdom, Wagners’ FRP solutions are redefining best practice in composite foundation design.

Wagners CFT Technical Lead, Dr Ali Mohammed and Chief Technical Officer, Michael Kemp say to truly understand the durable and lightweight nature of FRP, you need to look at the unique fibre layup.

“At Wagners, we’ve been pultruding fiberglass profiles for over 20 years and we’ve used those profiles for various different applications. We’ve used them in crossarms, we’ve used them in boardwalks and bridges,” Michael Kemp said.

“We’re making continuous cross-section profiles like steel or aluminium but out of fiberglass and we’ve adopted those profiles to different applications with piling being one that we’ve been working on for 15 years,” Mr Kemp said.

“Our 301 circular hollow sections (CHS) have 17 layers of fibers, all of them are individual rovings. We have the fibers that go in the zero direction which provide the main strength and stiffness but in between every longitudinal fiber layer, we have a transverse fiber layer which are also made of individual rovings,” Dr Ali Mohammed said.

“These individual rovings provide the transverse strength but more importantly they provide the confinement for the longitudinal fibers which make them very stiff compared to traditional FRP. That enables them to take the impact from the hammer or to drive these FRP piles without exceeding their driving stress,” Dr Mohammed said.

Pictured – Fibreglass rovings used to pultrude Wagners FRP profiles.

Pictured – Fibreglass rovings used to pultrude Wagners FRP profiles.

Wagners’ first piling project took place in Mackay, Queensland, where challenging conditions and limited access highlighted the advantages of lightweight and low maintenance FRP materials.

“The first composite pile project that we undertook was up in Mackay. The council was looking to put in a walking trail system called the Bluewater Trail that extends all around Mackay,” Michael Kemp said.

“On the initial site inspection, we found an old bridge that was completely rusted out, so we knew that we were going into an area where traditional materials were going to struggle and that a composite boardwalk would be first choice for council due to the lower maintenance requirement long term,” Mr Kemp said.

“The benefits of composites in this type of environment include the corrosion benefit. They’re also very light so two men were easily carrying 6 metre lengths onto site. We had a fairly narrow area where we were allowed to have machinery, so all the gear was being carried along the length of the boardwalk so we found lightweight materials greatly helped installation costs,” he said.

“As our first commercial project, we had done some trials before the project but across the course of this project with over 410 piles driven, we used it to really get used to piling and test a few different things.”

“Across the course of the project we did dynamic load testing. We also set up concrete blocks and a structural support frame and were able to do static testing. We were correlating that to the Hiley formula so we could determine based on the mass of the hammer and the height it drops, effectively using the energy equation you can reverse calculate the vertical capacity of that pile.”

“This initial project gave us a lot of confidence in the use of composite piles in projects and it’s become a staple. I’d say we’ve driven tens of thousands of piles since that initial project on boardwalk and pedestrian bridge style projects all around Australia, the US and the UK.”

Pictured – The first piling job completed in Mackay, Queensland.

Pictured – The first piling job completed in Mackay, Queensland.

Depending on the contractor’s preference and skill set, either drop hammers, vibratory hammers or impact hammers can be used to drive the FRP piles.

“When it comes to the driving and installation of these FRP piles, there are several methods that can be used. Any of these methods can be implemented, it mainly depends on the contractor preference and the contractor capacity in terms of what equipment they have on site and what experience their operators have,” Dr Ali Mohammed said.

“The drop hammer like everything else has its pros and cons. The beauty of the drop hammer is that it can be used for driving and also used to verify the axial capacity of these specific piles by checking the pile set per drop. A vibratory hammer also can be used,” Dr Mohammed said.

“Another option is the impact hammer, which is basically a rock breaker mounted on the excavator. The impact hammer provides several impacts per second and drives the pile into the ground,” he said.

“Impact hammers are being increasingly used now in the piling industry. The beauty of the impact hammer is that it is very efficient and very quick and minimises the installation time substantially.”

Pictured – A drop hammer used for pile driving in south-west Queensland.

Pictured – A drop hammer used for pile driving in south-west Queensland.

FRP is fully resistant to rot, rust and corrosion in saltwater making FRP piles the perfect solution for marine environments.

“In addition to its durability, FRP is utilised because it can survive in marine environments, whereas traditional materials can severely struggle especially in harsh marine environments. Timber piles deteriorate badly and steel piles corrode,” Dr Ali Mohammed said.

“We have FRP posts/piles in a project installed in the Brisbane River which have survived two floods. The FRP members have been in service for 12 years with no signs of deterioration of the FRP, and still can meet and exceed the published design value and QA pass marks,” Dr Mohammed said.

“To give a direct comparison on the performance between FRP and other traditional materials, the below photo was taken of a beach access structure which contains FRP components. The structure was installed 10 to 12 years ago,” he said.

“The two posts at the bottom of the structure were damaged by vandalism and the council engaged a local contractor to replace the damaged FRP posts.”

“The local contractor used carbon steel to replace the two bottom FRP posts and just after 18 months in service, you can see how they have severely corroded in the harsh marine environment compared to the fresh looking FRP posts which have been in service for more than 12 years.”

Pictured – A direct comparison between the performance of FRP (back posts) and carbon steel (front two posts) in a marine environment.

Pictured – A direct comparison between the performance of FRP (back posts) and carbon steel (front two posts) in a marine environment.

To increase the level of protection for piles subjected to intense impact in harsh marine environments, piles can be encased in a high-density polyethylene (HDPE) sleeve.

“The design work we’ve done gives us the confidence to say that we’ve got a solution for piling and understand there’s many different environments and different styles of pile that are needed,” Michael Kemp said.

“Particularly in these marine environments, we’ve developed a HDPE coating that goes on the outside of our piles to create what we call the ‘Trident Marine Pile’. It is the same fiberglass profile but this time with a HDPE sleeve integrally connected to the outside,” Mr Kemp said.

“What we have seen is that in these marina type applications where you have floating structures connected to the piles, generally they’re connected by a frame with small wheels or bumper. As the tide comes in and out and they float up and down on the pile, they rub or wear or braid onto the pile itself,” he said.

“The HDPE coating in these instances is designed for these types of environments where you have a constant abrasion or a constant impact on the pile. We see them being used particularly in residential marina type applications or in areas of high debris loading where additional armoring on the pile would be warranted.”

Pictured – FRP marine piles encased in a HDPE sleeve.

Pictured – FRP marine piles encased in a HDPE sleeve.

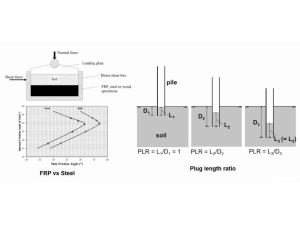

Design notes to take into consideration when designing with FRP piles include the skin friction angle between FRP and the soil, compared to traditional materials and the plug length ratio.

“A direct shear test has been undertaken on two samples, FRP and steel by having the FRP and the steel samples with the soil on top with a perpendicular load to provide that compression force and also a sheer force to measure the skin friction angle between the soil and the pile material”, Dr Ali Mohammed said.

“For that specific type of soil, five soil samples were used with different internal friction angles. For the same soil type, the FRP provided higher skin friction angle, which means the shaft adhesion we get from the normal geotech reports, it’s slightly conservative I would say by 30% when it comes to the FRP piles,” Dr Mohammed said.

“The other component which is applicable here, and basically to all hollow piles, is the plug length ratio. This means when driving the pile into the ground, the soil will go to the inside of the FRP pile, to a specific length, creating a plug/solid bearing surface plug,” he said.

“Based on that, what can be considered here is the internal shaft adhesion of this FRP pile considering the plugging effect from the inside, which can be simplified/translated to an additional factor on the outer surface/shaft adhesion of the FRP pile (Gudavalli et al.).”

“Based on this study, the factor can vary between 1.1 up to ~1.6, or it can be simplified by considering the plug as a surface/bearing area at the bottom of these relatively small FRP piles.”

Pictured – Designed considerations for hollow FRP piles (Aksoy et al.).

Wagners CFT continues to develop new products to meet more clients needs and provide high quality FRP profiles for a large variety of projects.

“Coming soon we will have larger diameters. So today, most of the early work that we did with our pedestrian structures are 100×100 or 125×125 millimetre square profiles. Most of the work Ali is working on there at the moment is using our larger circular 300 millimetre diameter and 356 millimetre diameter profiles,” Michael Kemp said.

“Pultrusion is a fantastic process with lots and lots of volume. The 301 and 356 we’re using as power poles and piles so it doubles up, it’s got quite a large demand for it,” Mr Kemp said.

“For smaller quantities, hundreds as opposed to thousands, filament winding is the preferred method. So we are putting in a filament winder at CFT to produce power poles and piles,” he said.

“The length of the products we’ll produce will be up to 15 metres in length and up to an 800 millimetre diameter. So we’ll be able to produce some large profiles.”

“Early next year these will be available and we’re ready to start talking about supply today.”

“We know people are often buying composite products so that they get a long-life asset and we are very motivated to ensure that that is achieved.”

To watch the full webinar on piling featuring Wagners CFT Technical Lead, Dr Ali Mohammed and Chief Technical Officer, Michael Kemp, visit https://www.youtube.com/watch?v=JswjeKd4Hvs

For more information on Wagners FRP piles, visit https://www.wagnerscft.com.au/solutions/marine-infrastructures/trident-marine-piles/

To download our Trident Marine Pile brochure, visit https://www.wagnerscft.com.au/app/uploads/2024/07/TRIDENT-MARINE-PILES-2.pdf

Pictured – Wagners FRP piles on a barge in Papua New Guinea ready for piling.

Pictured – Wagners FRP piles on a barge in Papua New Guinea ready for piling.