When the original Lea Lea footbridge collapsed in late 2023, it left the local Papua New Guinean community without a safe crossing over the Rea Rea inlet.

To reconnect the villages, work began on a new, more resilient structure constructed from Fibre Reinforced Polymer (FRP), an innovative material ideal for the coastal environment. Designed with local input, the new FRP bridge reflects a careful balance of innovation, practicality and community needs.

Overseeing the project from concept to completion was Turra Holdings Limited Project Manager, Tom Derby.

“The original Lea Lea footbridge was constructed in 2012 under an Exxon Mobile tax credit project and while they did a really good job of the decking, the support structure wasn’t the best and they had poles that were of fairly inferior quality,” Tom Derby said.

“The structure is across this Rea Rea inlet which is around 40 kilometres west of Port Moresby in Central Province. The total length of the crossing is 220 metres.” Mr Derby said.

“Apparently there was an expat who came to the area many many years ago and misheard the name of the village and it’s been called Lea Lea ever since, but it was actually called Rea Rea,” he said.

“The existing structure collapsed in October 2023, so the locals had to rely on ferrying across the river.”

“They did an excellent job at building a temporary structure just with local labour. They got mangrove poles, used the existing deck structure and in about five or six weeks they built a temporary structure which allowed the locals again to cross over the bridge site.”

“A bit fortuitous for us, this bridge structure collapsed about two days before we actually started construction and that made construction for us quite a bit easier.”

Pictured – The original timber Lea Lea footbridge.

Pictured – The original timber Lea Lea footbridge.

During the planning phase of the project, Turra Holdings Limited spoke with the locals about what they hoped for and considered both local and imported products.

“We did speak to the locals about what sort of structure they wanted as a replacement. They insisted they didn’t want any vehicles or traffic in their village and wanted to stick with the footbridge structure, so we decided on a two-metre-wide deck which is pretty similar to what was there originally,” Tom Derby said.

“The Department of Works and Highways contacted Turra to put together pricing for a design and construct solution for the replacement bridge with the project again being funded under the Exxon Mobile tax credit program,” he said.

“We had a gentleman who’s been in Papua New Guinea a long time and he’s a consultant to the Department of Works and Highways. He had heard of the Wagners product and suggested we contact Wagners and get something underway.”

“Through contacting Wagners CFT Chief Technical Officer, Michael Kemp, a proposal and pricing for FRP were put together.”

“Papua New Guinea for the last probably 10 years has had a real problem in foreign exchange so to get foreign exchange to buy products from outside Papua New Guinea, there can be a waiting time of anything, depending on the size of the order, of up to six months.”

“Because of that, we went to look at an internal supplier who provides timber decking and got a proposal put together which involved steel piles and a steel superstructure, which again had to be imported but the timber decking would have been locally manufactured.”

“We took that to the clients, the Department of Works Steering Committee and they agreed that the Wagners CFT solution is much superior mainly due to minimal maintenance requirements and the fact that it’s in a marine environment made that even more important.”

Pictured – The original timber Lea Lea footbridge next to the new FRP footbridge.

Pictured – The original timber Lea Lea footbridge next to the new FRP footbridge.

Wagners Composite Fibre Technologies (CFT) Chief Technical Officer, Michael Kemp played a key role in the design phase of the project.

“After we got through a tender process and Wagners CFT were commissioned, we got straight into the detailed design phase,” Michael Kemp said.

“The first thing that we were looking at even before commissioning was what type of structure is going to best suit the local location and what spans are we looking at. We were able to put together ballpark cost estimates based on different configurations,” Mr Kemp said.

“A previous project we had completed in South West Rocks was used as a guide and had roughly seven metre spans between bents and roughly a 375mm deep girder and effectively a 1,800mm trafficable width on that walkway,” he said.

“We were able to put together an order of magnitude cost estimate based on a series of those spans for the length of the structure and then the same but based on a 24-metre span.”

“Typically we’re operating from six meter to 30-meter span configurations at Wagners CFT regularly and we’re looking to push that envelope on larger span structures, but the bulk of our work today is in that range.”

“So we could compare the cost differential between seven-meter spans and 24-meter spans and whilst when you go to the larger spans, you’re getting a higher cost per square meter in your superstructure, you’re getting a lower cost in your piling because you’re putting in a smaller number of piles.”

“Each pile group will need to carry more load so it’s always this trade-off or balancing act between the size of the piles, the span of the superstructure and at the end of the day making sure we get the right result.”

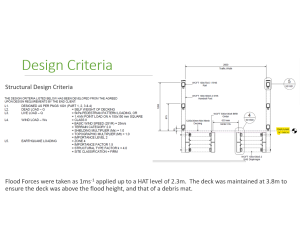

Pictured – The structural design criteria.

Pictured – The structural design criteria.

When it came time to determine how best to span the walkway, the team turned to both local expertise and clever engineering to balance design simplicity with structural performance.

“So we were talking to Tom and his team about what sort of size or what sort of mass they could lift. A 24-meter span truss needs a much bigger crane than a seven-meter span,” Michael Kemp said.

“We engaged Kramer, an engineering firm that has offices here in Brisbane but also very local in Port Moresby from that basis. So good familiarity with both to take what Wagners knows well, which is Queensland and Australian design criteria and correlate that with the local requirements in PNG,” Mr Kemp said.

“From a cross-section point of view, we went with a 10-meter span. The difference between our earlier versions was that we’d recently come up with this 250 x 100 pultruded profile,” he said.

“We’re bonding two of those together to make a 500mm deep bonded girder. And we could use four of those girders across the width of the walkway to meet the requirements. So we’re able to achieve that two-meter width inside the handrails with those four girders.”

“We like the cross-section methodology to be fairly simple. Four girders, some diaphragms and handrail posts bolted directly onto the outside of the exterior girders.”

Pictured – Two 250 x 100 pultruded profiles bonded together.

Pictured – Two 250 x 100 pultruded profiles bonded together.

Piling presented some early uncertainty, with onsite conditions differing from the initial geotechnical reports and requiring flexible solutions.

“One of the key issues with piling is that you never quite know what you’re going to hit,” Michael Kemp said.

“The geotech report was taken slightly upstream from the exact location that we were working off, so we initially had quite a few questions between Tom and myself, on how we were going to handle the piling,” Mr Kemp said.

“There were reports of a deep layer of silt which initially we thought we wouldn’t be able to get any capacity out of but when we got to the site, that silt layer was not there. It was probably upstream where the test was taken, not where we were so we did design the piles with splicing in mind,” he said.

“It was Michael that recommended that we should go down with an undersized drill so we ended up buying a 250mm diameter augur that could go down a maximum of nine metres,” Tom Derby said.

“And then Michael recommended driving the piles with either a vibratory hammer or impact hammer,” Mr Derby said.

“We also purchased a side grip vibratory hammer which turned out to be extremely useful to pick up the piles, manoeuvre them, put them in position and drive them down as far as they could go. That worked out really well, it was a saver for us,” he said.

“To finish off the piles, we got a relatively small rock breaker, designed a 50mm steel plate that we put on the end of it and we used that as an impact hammer to finish the piles down to design depth or refusal.”

Pictured – A preassembled double beam section being craned into place during construction.

Pictured – A preassembled double beam section being craned into place during construction.

The initial phase of construction focused on refining the piling process.

“We installed the first five bents from the beach just using a frame on the ground and that allowed us to figure out the installation procedure with the augur,” Tom Derby said.

“The auguring was the critical thing. If you get the hole in the right place, the pile will follow and we found that all the way through,” Mr Derby said.

“After the first five bents, we had a decent sized barge 50 x 12 metres and we moved that with, I think we had to do eight shifts. We could drive two bents from each barge location,” he said.

“So we were driving the piles, we just needed to get a decision on what the minimum depth was. There were a few queries about HAT but we finished up with a minimum penetration of 4.5 metres.”

“Initially we drove some of them down to 8 metres depth and we had to splice one bent where we went a bit too far with the pre-drilling.”

“The splices were very simple to put in. They were external splices where you can see the bolts. Four bolts top, four bolts bottom on opposite axis and that went very easily. No problem.”

Pictured – A preassembled double beam section being craned into place during construction.

Pictured – A preassembled double beam section being craned into place during construction.

Watching the bridge come together on-site showcased not only the lightweight, modular advantages of FRP, but also the team’s ability to confidently adapt to the new material.

“So Michael came up for a site visit one day and he looked at me and he saw these guys, 12 of the guys had the slings around the 12 metre pile and he said, “Goodness, these guys aren’t going to pick that up, are they?” and they picked it up, no problem, moved it around, set it in front of the excavator and allowed the excavator to pick it up,” Tom Derby said.

“So, it’s very easy to work with. And again with the lightweight nature of the beams together were about 400 kgs each beam, so it was quite easy to lift them into place with the excavator,” Mr Derby said.

“We had a yard about 20 kilometres from the bridge site where we preassembled the double beam sections then drove them to site,” he said.

“We had a Wagners CFT technician come, he spent overall three weeks there and explained to the guys how to do all the pre-assembly and then the installation of the headstocks and the bridge superstructure on site.”

“It really worked out very well and it was very simple to go together. Once the guys had been schooled on putting all the beams together and the decking and the whole superstructure, they just worked themselves and had no problems at all. They did a great job.”

“As I say to everybody, it’s the best-looking bridge in Papua New Guinea.”

For more details on the project, watch the full webinar ‘Case Study: Lea Lea Bridge’ – https://www.youtube.com/watch?v=QPanWAyCEws&t=893s

To read more about the Lea Lea bridge project, visit – https://www.wagnerscft.com.au/project/lea-lea-bridge/

For more information on piling with Wagners FRP, watch – https://www.youtube.com/watch?v=JswjeKd4Hvs&t=595s

Pictured – The completed Lea Lea Bridge (Rea Rea Footbridge) during the opening ceremony.

Pictured – The completed Lea Lea Bridge (Rea Rea Footbridge) during the opening ceremony.